In heavy-duty work environments, mobility and load management are critical for efficiency and safety. Pneumatic castors, known for their air-filled wheels and shock-absorbing properties, are ideal for handling heavy loads across challenging terrains. From construction sites to industrial warehouses, pneumatic castors offer numerous advantages, ensuring smooth movement, stability, and durability. In this blog, we’ll explore pneumatic castors' benefits and common uses and why they’re a smart choice for heavy-duty applications.

1. What Are Pneumatic Castors?

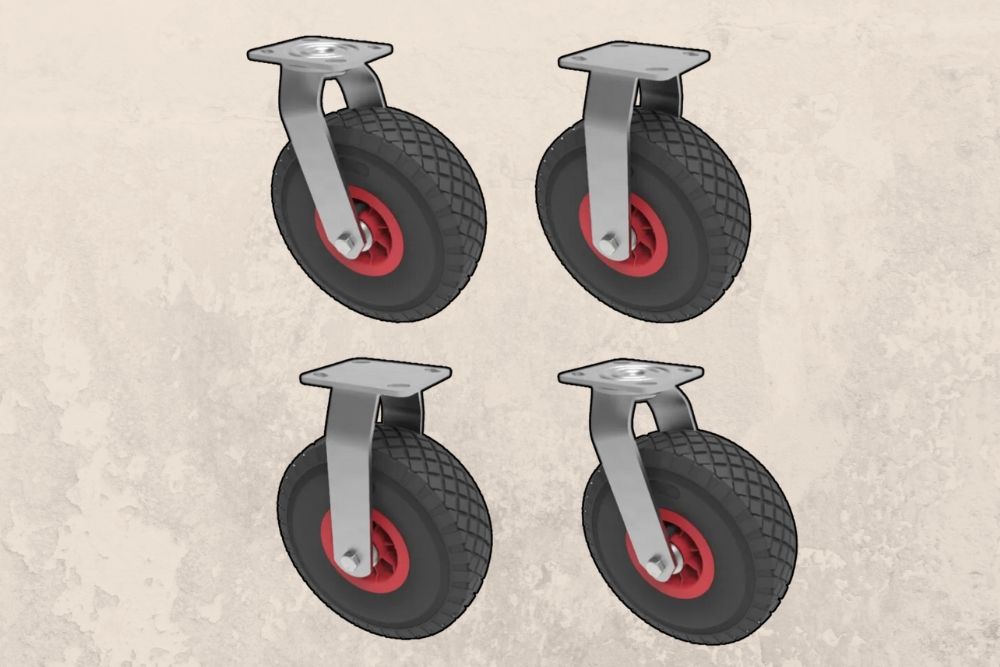

Pneumatic castors are equipped with wheels filled with air or foam, like those on bicycles or vehicles. These wheels are mounted on sturdy castor frames, making them capable of handling uneven surfaces while reducing vibrations and shocks.

Key Features of Pneumatic Castors:

- Air-filled or foam-filled wheels for flexibility.

- Excellent shock absorption for smooth mobility.

- Durable construction for heavy-duty loads.

Their unique design makes pneumatic castors particularly effective in environments where traditional castors might struggle.

2. Benefits of Pneumatic Castors

a. Shock Absorption for Smooth Mobility

One of the standout benefits of pneumatic castors is their ability to absorb shocks. This is especially important in heavy-duty environments where loads often encounter rough or uneven surfaces.

- Benefit:

Reduced vibration protects sensitive equipment and cargo. - Ideal for:

Transporting fragile items or machinery prone to damage from jolts.

b. Enhanced Manoeuvrability on Uneven Surfaces

Pneumatic castors are designed to easily navigate challenging terrains, including gravel, grass, and cracked concrete.

- Benefit:

Improved control and stability in outdoor and industrial settings. - Ideal for:

Construction sites, warehouses, and agricultural operations.

c. Reduced Noise Levels

Unlike solid or hard castors, pneumatic castors offer quieter operation, making them suitable for environments where noise reduction is essential.

- Benefit:

Quieter movement enhances worker comfort. - Ideal for:

Hospitals, workshops, and other indoor environments.

d. High Load Capacity

Despite their cushioning properties, pneumatic castors are built to handle substantial weights, making them suitable for heavy-duty applications.

- Benefit:

Combines strength with smooth mobility. - Ideal for:

Moving bulky equipment or heavy industrial supplies.

3. Common Uses of Pneumatic Castors

a. Construction and Outdoor Worksites

In construction, the terrain is often uneven, with obstacles such as rocks, mud, or debris. Pneumatic castors provide the stability and flexibility needed to move equipment and materials efficiently in these conditions.

- Example:

Mobile scaffolding, tool carts, and heavy-duty trolleys.

b. Warehousing and Industrial Applications

In warehouses and factories, pneumatic castors help move loads across different surfaces, including polished concrete, ramps, and loading docks.

- Example:

Pallet trucks, material handling carts, and storage trolleys.

c. Healthcare and Maintenance

Hospitals and maintenance teams benefit from the quiet and smooth movement of pneumatic castors, especially when transporting delicate medical equipment or tools.

- Example:

Hospital beds, maintenance trolleys, and portable equipment racks.

d. Agriculture and Farming

In agricultural settings, pneumatic castors are perfect for navigating uneven, soft ground like fields and pastures while carrying heavy equipment or feed.

- Example:

Feed carts, irrigation equipment, and portable machinery.

4. How to Choose the Right Pneumatic Castors

a. Consider Load Capacity

Ensure the pneumatic castors you select can handle the weight of your equipment and loads. Overloading can reduce their lifespan and compromise safety.

b. Match the Terrain

For rough outdoor terrains, opt for pneumatic castors with larger wheels and sturdy treads for better grip and stability.

c. Material and Construction

Choose castors made from high-quality materials to ensure durability in heavy-duty environments. Steel frames and reinforced wheel designs are ideal.

d. Maintenance Requirements

Pneumatic castors require regular maintenance to maintain proper air pressure and ensure optimal performance. Foam-filled options are a low-maintenance alternative.

5. Maintenance Tips for Pneumatic Castors

- Inspect Air Pressure: Regularly check and maintain the correct air pressure to ensure smooth movement and prevent wheel damage.

- Clean Regularly:

Remove debris, dirt, or mud that can accumulate on the wheels or axles. - Lubricate Bearings: Keep the bearings well-lubricated for seamless swivelling and rolling.

Routine maintenance helps extend the life of your pneumatic castors and ensures consistent performance.

Conclusion:

Pneumatic castors offer a unique combination of strength, flexibility, and shock absorption, making them indispensable for heavy-duty work environments. Whether navigating rough outdoor terrain or ensuring the safe transport of delicate equipment, pneumatic castors provide the durability and performance needed to get the job done. Explore a wide selection of high-quality pneumatic castors at Castors Online and find the perfect fit for your workplace needs.